To meet the high-level needs of knee replacement-the world's first 3D printed partitioned trabecular bone bio-type knee prosthesis was successfully implanted in

Jan. 10, 2022

Jan. 10, 2022

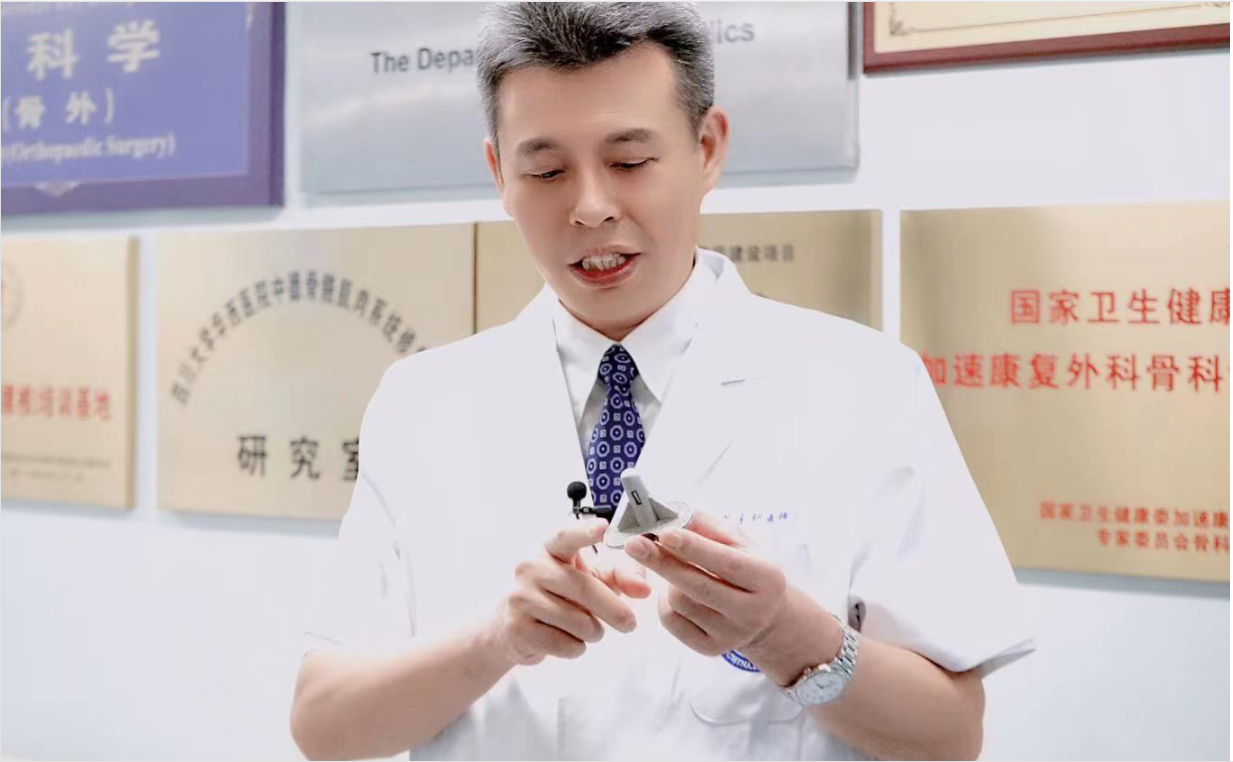

September 30, 2021, led by Professor Zhou Zongke from West China Hospital of Sichuan University, the world's first 3D printed partitioned trabecular bone bio-type knee prosthesis designed and manufactured by Just Huajian Medical Devices (Tianjin) Co., Ltd. was in Sichuan Successfully implanted in West China Hospital of University! On October 19, the patient had returned to normal walking during the follow-up review, with satisfactory knee joint function.

The clinical application of this project breaks through the limitations of the current conventional treatment of knee arthritis and brings good news to the majority of knee arthritis patients. Many mainstream media have followed up and reported the world's first 3D printed trabecular bone bio-type knee prosthesis project!

Professor Zhou Zongke, director of the Department of Orthopaedics and Secretary of the Party Branch of West China Hospital of Sichuan University, mentioned in an interview: "Knee osteoarthritis is a degenerative disease of the knee joint, with a high incidence in middle-aged and elderly people. With economic development and aging The trend is becoming more and more obvious, and the demand for knee replacement surgery is increasing. In addition, patients have higher requirements for the quality of life and prosthesis life after knee replacement, which brings new ideas to the design and development of prostheses. The world’s first 3D printed partitioned trabecular bone bio-type knee prosthesis came into being under this new situation of high demand and high expectations.

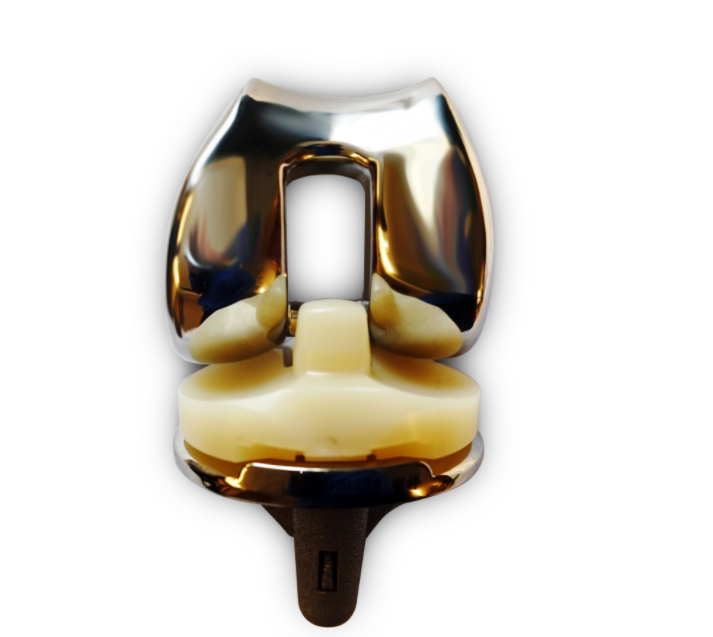

The knee joint prostheses currently in clinical use are mostly cement-fixed prostheses. Bone cement is a bone cement, which can fix the knee joint prosthesis on the bone interface. But bone cement fixation may have certain problems, such as bone cement monomer has a certain toxicity; bone cement and bone contact surface osteolysis problem; bone cement will deform and degenerate over time, and the ability to withstand stress decreases. The bio-type knee prosthesis implanted this time was developed and manufactured by Just Medical. It does not require bone cement during the operation. Through mechanical fixation, the prosthesis and bone tissue are closely combined to obtain the initial stability of the prosthesis. Bone tissue grows into the micropores on the surface of the prosthesis to realize the transformation from mechanical fixation to biological interlocking fixation, and finally obtain good fixation through osseointegration, and it is expected that a longer prosthesis life can be obtained.

The biggest highlight of this 3D printed partitioned trabecular bone bio-type knee prosthesis is that the tibial platform prosthesis uses 3D printed trabecular bone partitioning technology. The three-partition design allows the host bone to grow evenly and avoid uneven stress distribution. Problems such as loosening of the platform prosthesis. Really realize that bones grow faster, grow more evenly, and grow stronger, and meet the high-level needs of more knee arthritis patients.

Just medical through the mechanism of "industry-university-research" fully integrated, realize the "enterprise + hospital + key laboratory" trinity integrated innovative research and development, at the same time, just medical has a 3D printing workshop, intelligent equipment clusters, and finally form artificial joint 3D The integrated platform for R&D and manufacturing of printing technology has laid a solid foundation for the successful application of new products and technologies.

The successful application of the world’s first 3D printed zonal trabecular bone bio-type knee prosthesis means that Chinese hospitals and companies choose to develop higher-end, safer and more effective products that are suitable for Chinese people based on the needs of Chinese patients. Innovations in technology and products are crucial to solving the growing medical needs of clinical patients! As a national high-tech enterprise, Just Medical has realized the leap from "Made in China" to "Intelligent Made in China" for artificial joint prostheses in the context of technological innovation!